04/24

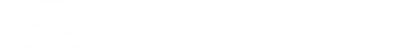

Sharp edges require extra processing costs and time; Wall thickness changes can leave unsightly indentation and edge biting, although can be on the mold side action, but increase the cost and cycle time.

04/24

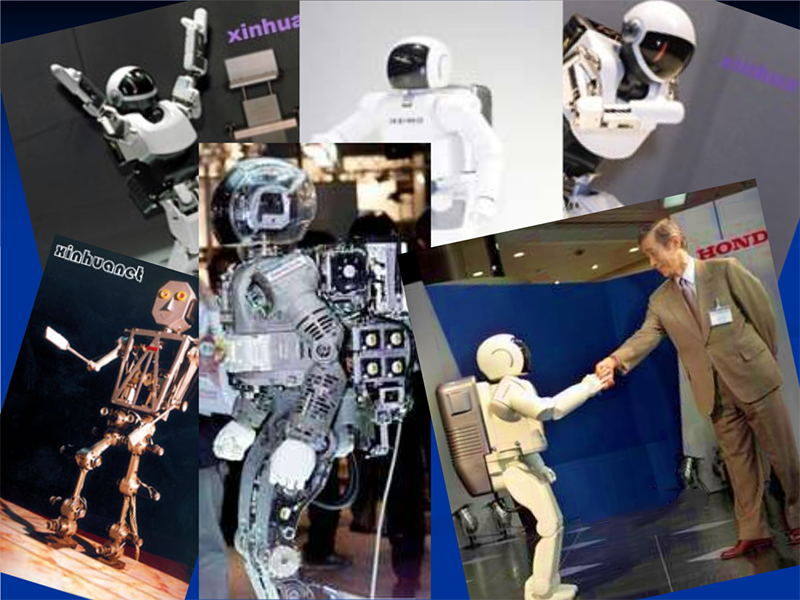

Deciding which manufacturing process to choose can be difficult; There are many different factors to consider. You can start with the die casting process, as it can provide the quantity you need and meet your required tolerances. However, you may need to switch to a different manufacturing process next. This can happen if the demand for parts changes, or if your delivery cycle or quality needs to change.

04/24

Steel comes in many forms: sheet metal, plates, bars and beams in all geometric shapes, pipes, and of course the solid materials used in CNC processing steel. Steel is used in so many applications and in so many industries that it makes sense to have many different types of steel. But what's the difference between stainless steel and mild steel? Free machined and tool steel? In this article, you will learn about many types of machined steel and how to successfully CNC machined steel.

04/24

surface roughness refers to the micro-geometric errors composed of small spacing and tiny peak-valley on the processed surface, which can be understood as the roughness of fine spacing and tiny peak-valley in the process of processing products. The smaller the geometrical error of the machined surface is, the higher the surface accuracy is. Otherwise, the lower it is.

04/24

Aluminum is one of the most abundant metallic elements found in the Earth's crust, and it is also the most widely used non-ferrous metal. Aluminum can be used in common objects, such as aluminum foil or aluminum cans, or in extreme specialized applications, such as parts for spaceships and submarines.